In the News | COVID-19 Update: Connecticut Engineer, 3D Printer Answer Doctor’s Call to Create Ventilator Splitter

Norwich, CT (CT News Junkies, March 29, 2019) — State Sen. Saud Anwar, whose day job as a medical doctor specializing in lung disease and critical care has kept him extremely busy over the past several weeks, shared what may be a big breakthrough Saturday in the effort to prepare for a surge in acute cases of COVID-19.

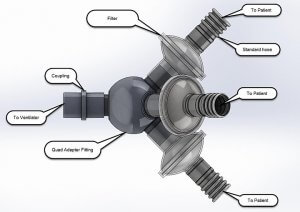

In a video posted to his Facebook page from Manchester Memorial Hospital, Anwar details a new, open-source 3D-printed valve – the Ventilator Quad Splitter – that could allow a single ventilator to treat up to seven patients per unit.

Conley’s illustration of his Ventilator Quad Splitter design (contributed photo)

“We’ve been working collaboratively together as a group of people from different backgrounds to get this done,” Anwar said.

Ventilators – which keep people alive when their lungs have failed – are in high demand at acute care hospitals with the spread of COVID-19. Manufacturers of many types are working around the clock to convert their production lines with a goal of making new ventilators.

But that may take too long, so Anwar posted a request for help last week with a goal of increasing the capacity of the ventilators that are already in use.

Anwar’s request was posted in some user groups online and was seen by Kevin Dyer, CEO at InterPRO Additive Manufacturing Group in Deep River, which uses 3D printing to create new parts and products.

Things moved pretty quickly from there.

Dyer also did some outreach and said he would print a prototype if someone would help with design. He found Robert Conley, a mechanical design engineer who is an associate professor at Three Rivers Community College and also has his own design firm, Interactive CAD Solutions. Conley, of Lebanon, started designing the new valve apparatus Wednesday, completing it Thursday and transmitting the specifications to Dyer.

Conley said Dyer then printed the valve overnight and handed it to him outside Manchester Memorial Hospital on Friday morning.

Clockwise from top left: Anwar, Conley, Bristol, and Dyer (contributed photos)

“I went in and met with Saud,” Conley said, adding that there were some initial issues. He noted some new information about how the ventilators function, including the requirement that each inlet and outlet must have a HEPA filter. The valve was designed using the Nellcor Puritan Bennett 840 Ventilator System. However, Conley said the fitting is based on a standard 15mm diameter, which he said is a universal size in ventilators of this type.

Conley said he redesigned it Friday afternoon with more room for the HEPA filters and at 4 p.m. sent the new specs to Dyer, who then produced the new model overnight.

On Saturday, Anwar posted the video showing the functional Ventilator Quad Splitter.

“This valve actually has four options, so we can have four connectors with just one ventilator and each connector can further be divided into two or more branches if we need to,” Anwar said. “It can provide breathing capacity and help to not one, not two, not three, not four, not five, but actually seven people and can go up to eight if we need to.”

Anwar added that each patient gets “a volume based on the exact settings that we have set up.”

The valve is a prototype and will need regulatory approvals before it can be sold, but Respiratory Specialist Marvin Bristol, who appeared in Anwar’s video, said the valve works.

“It’s just a concept that works in a simulation, and if it comes down to mass casualties this is a concept that I believe can be tried in the field, if need be, to have a clinical trial,” Bristol said. “The concept works.”

Anwar said that they were able to lengthen the tubes to 20 feet without losing pressure.

Conley also added that the design is open source, and the files for 3D printing are available on his website at intcadsol.com/ventilator-quad-splitter.

With all that said, the idea of increasing individual ventilator capacity was a cause of concern last week from several groups within the medical community. The Society of Critical Care Medicine, the American Association for Respiratory Care, the American Society of Anesthesiologists, the Anesthesia Patient Safety Foundation, the American Association of Critical‐Care Nurses, and the American College of Chest Physicians issued a consensus statement on March 26 against the concept of placing multiple patients on a single mechanical ventilator.

They said sharing mechanical ventilators should not be attempted because it cannot be done safely with current equipment, and recommended that clinicians not attempt to ventilate more than one patient with a single ventilator while any clinically proven, safe, and reliable therapy remains available.

— By Walker Strong, CT News Junkies writer

The original article can be found here: “COVID-19 Update: Connecticut Engineer, 3D Printer Answer Doctor’s Call to Create Ventilator Splitter”

Watch this Fox 61 New story on Conley and the Ventilator here, “Ventilator invention: Yankee ingenuity may allow one ventilator to help 7 patients.”

.